Model:YGX82 6 axis load cell

Features & Applications:

Made of high-strength aviation aluminum alloy, small size, light weight and high strength;

The international high level strain gauge chip is adopted, which can achieve high resolution, high response frequency and high test precision points;

100% independent structural design, carefully tested before delivery, and extremely high coupling accuracy;

Multiple communication interface protocols can be selected, basically covering the mainstream cooperative robot interfaces at home and abroad;

Provide debugging software or testing software;

Bending resistant high flexible cable;

Suitable for robot force control grinding, assembly, drag teaching and various scientific research;

Capacity: Fx/Fy/Fz:50/200/500N Mx/My/Mz:2/10/20Nm (Custom-made is available)

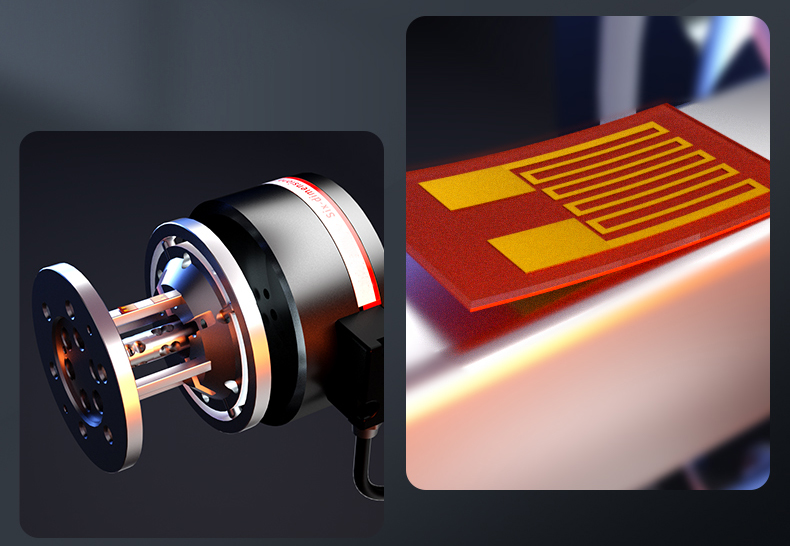

Product picture

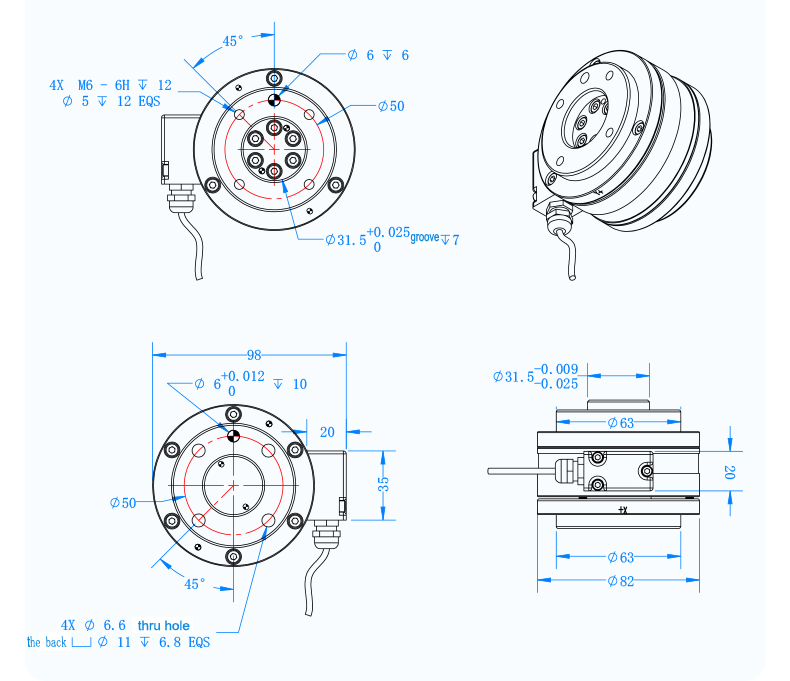

Dimensions(mm)

Specifications:

|

Model

|

YGX82-50N

|

YGX82-200N

|

YGX82-500N

|

|

Capacity

|

Fx/Fy/Fz

|

50N/50N/50N

|

200N/200N/200N

|

500N/500N/500N

|

|

Mx/My/Mz

|

2Nm

|

10Nm

|

20Nm

|

|

Mechanical characteristic

|

|

Weight

|

About 500g

|

|

Size

|

Φ82mm×41mm

|

|

Protection class

|

IP65

|

|

Overload

|

300%FS

|

|

Rigidity

(Calculation)

|

Fx

|

1.6x107 N/m

|

|

Fy

|

1.6x107 N/m

|

|

Fz

|

1.3x107 N/m

|

|

Mx

|

6059.99Nm/rad

|

|

My

|

6059.99Nm/rad

|

|

Mz

|

10056.99Nm/rad

|

|

Electrical characteristics

|

|

Input/output impedance

|

350Ω

|

|

Communication interface

|

Mv matrix

|

|

Working voltage

|

5-15V DC

|

|

Cable length

|

3m

|

|

Accuracy class

|

|

Resolution ratio

|

Better than 0.1% FS

|

|

Nonlinear

|

Better than 0.2% FS

|

|

Accuracy

|

Better than 0.3% FS

|

|

Repeatability

|

Better than 0.2% FS

|

|

Coupling accuracy

|

Better than 1.5% FS

|

|

Temperature characteristics

|

|

Temperature zero drift

|

0.2%FS/10℃

|

|

Zero drift

|

0.1%FS/30min

|

|

Storage temperature

|

-25°C ~70°C

|

|

Operating environment

|

0°C~40°C,20~80% RH

|

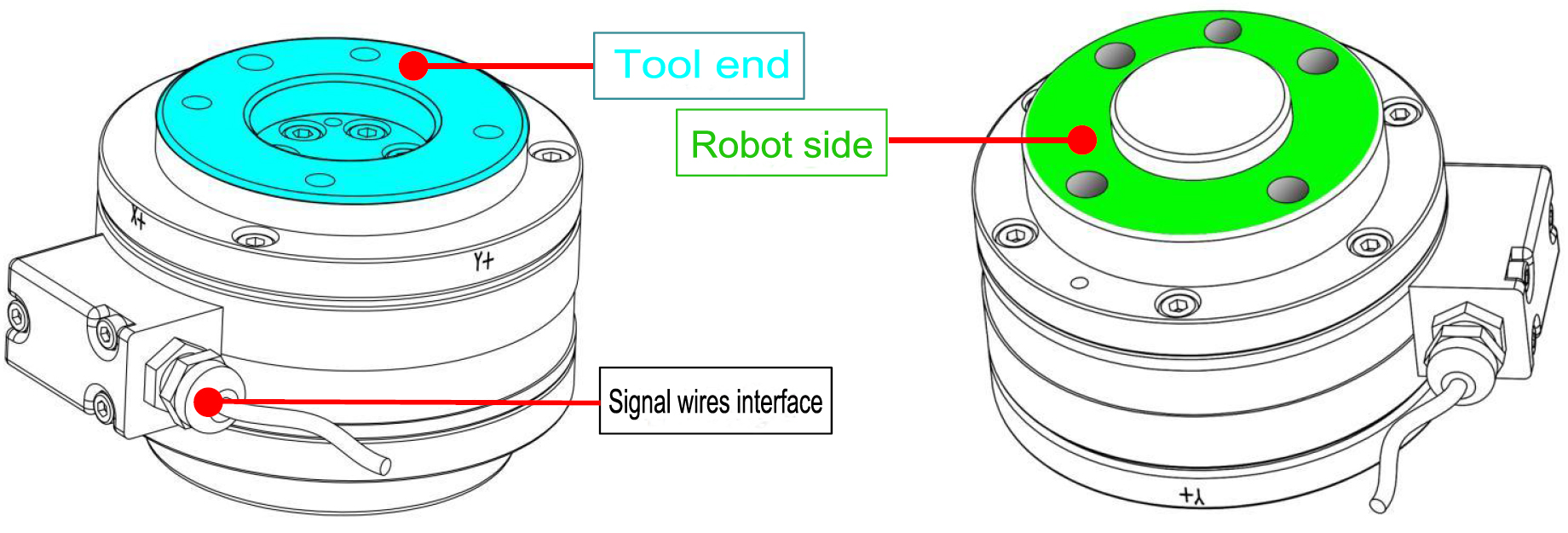

Sensor appearance structure

The force sensor contact surface (blue part) shown in the figure is the only allowed contact surface between the sensor and the tool, ensure correct force and torque feedback. The robot contact surface (green part) is between the sensor and the end of the robot,the only allowed contact surface is used to fix the sensor on the robot. Screw on tool end and robot end, the details of the bolt specifications and locating pins can be found in the specifications section. The bolts and pins connecting the robot end will included in the product package.

YGX82 sensor is specially designed and optimized for cooperative robot, with its own connecting flange, which can be connected with most of the the standard cooperative manipulator is connected seamlessly.

YGX82 sensor is designed as 90 ° right angle aviation plug or waterproof connector outlet, and tool end is used for assembly robot end tool, conforming to GB/T 14468.1-50-4-M6 or ISO 9409-1-50-4-M6 standards.

The robot end is a special flange for the connection between the sensor and the robot end, applicable to mechanical connection of GB/T 14468.1-50-4-M6 or ISO 9409-1-50-4-M6 standards.

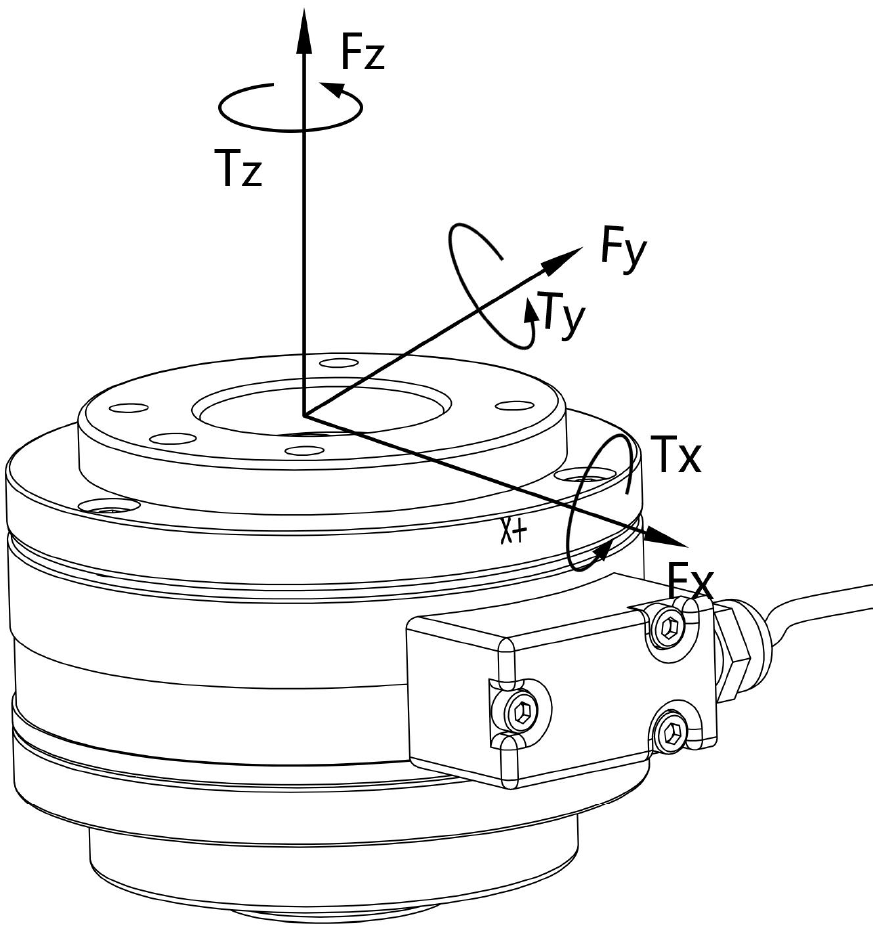

The coordinate system of YGX82 sensor, the X axis is perpendicular to the signal cable interface direction, and the positive direction points to the signal the outlet of the cable is in the opposite direction; The Y axis is perpendicular to the X axis, and the positive direction points to the pin hole of the sensor tool end; Z-axis sensing the axial center of the tool points to the tool end in a positive direction; the positive direction of torque conforms to the right-hand rule.

High quality strain gauge chip

Possible overload

Overload capacity introduction, which is a concern of multi-dimensional force sensor customers, and also an important reason for sensor failure (Sensor value is high, please contact our engineers for model selection)

1: The selection of measuring range shall not only consider the applied external force, but also fully consider the dead weight of fixture and workpiece and the bending moment generated by them.

2: The bending moment caused by the external force due to the force arm (the distance from the center of the sensor to the force point) shall be considered separately.

3: The overall dimension of the sensor is similar to that of the workpiece fixture.

Applications