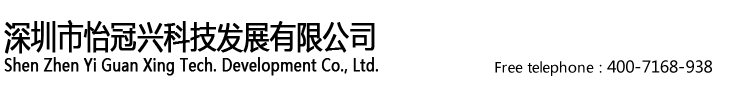

Model: YGX-ST120 Six axis force sensor

Features and Applications

Aluminum alloy six-dimensional force sensor

High rigidity, small deformation design

Suitable for scientific instruments, scientific research and other force test control application scenarios

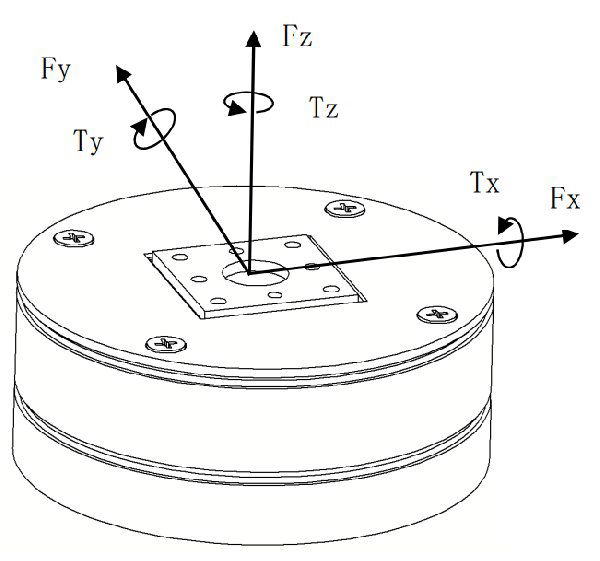

Dimensions(mm):

|

|

Fx

|

Fy

|

Fz

|

Mx

|

My

|

Mz

|

|

Capacity(N/Nm)

|

1000

|

1000

|

1000

|

20

|

20

|

20

|

|

Output(mv/v)

|

Decoupling

|

|

Bridge impedance(Ω)

|

350±3

|

350±3

|

350±3

|

350±3

|

350±3

|

350±3

|

Specification:

|

Capacity

|

Fx/Fy/Fz :1000N /1000N/1000N

Mx/My/Mz : 20Nm/20Nm/20Nm

|

|

Resolution

|

0.1% F.S.

|

|

Non-linearity

|

0.05% F.S.

|

|

Zero drift

|

0.2% F.S./10min

|

|

Accuracy

|

0.2% F.S.

|

|

Repeatability

|

0.2% F.S.

|

|

Zero temperature drift

|

0.2%F.S./10℃

|

|

Storage temperature

|

-25°C ~70°C

|

|

Use environment

|

0°C~40°C, 20~80% RH

|

|

Input resistance

|

350Ω

|

|

Output resistance

|

350Ω

|

|

Recommended excitation

|

6V

|

|

Interface form

|

16-pin aviation plug

|

|

Cable length

|

5m

|

|

Safe overload

|

400%

|

|

Protection Class

|

IP65

|

|

Weight

|

0.969kg(includes cable)

|

|

Sizes

|

Diameter:100mm Height:41mm

|

Assembly method: The upper assembly surface uses 6 x M4×7.5mm bolts, and the lower assembly surface uses 8 x M6×7.5mm bolts

Positioning method: The upper assembly surface adopts 2 x φ3×6mm pin holes, sliding fit, and there is a flat-bottomed hole with a φ14 depth of 2.5mm in the middle, which can be used for positioning. The lower assembly surface is provided with 2x φ5 deep 8mm pin holes, sliding fit.