Model: YGX-TQ1101 Micro-range dynamic torque sensor

Overview

YGX-TQ1101 micro-range torque sensor, the main application is for the micro-range (below 2Nm) torque measurement. When the torque measurement is less than 2Nm, the friction torque of the rotating body bearing bearing becomes a non-negligible interference factor. YGX-TQ11011 sensor, the strain zone and power supply, the launch area is arranged separately, so that the strain zone to avoid the impact of bearings, effectively improve and improve the torque sensor resistance to overload and measurement accuracy.

Product Features:

YGX-TQ1101 micro-range torque sensor is YGX-TQ1100 torque sensor of the small range: when the range is less than 2N • m, the sensor at both ends of the bearing bearing friction torque becomes a non-negligible interference factors. The structure difference between torque sensor YGX-TQ1101 and YGX-TQ1100 is to avoid the friction torque of the bearing interference.

Specifications

|

Range

|

0~±0.05N.m~±2N.m optional, (Custom-made,5Nm is available)

|

|

Power supply

|

±15V DC, 24V DC

|

|

Torque signal

|

5~15Khz, 4~20mA, 1~5V, 0-10V(optional)

|

|

Speed range

|

0~1000, 3000, 6000, 8000, 10000rpm

|

|

Speed signal

|

60 pulses / turn, 4-20mA, 1~5V

|

|

Accuracy

|

±0.25%, ±0.5%

|

|

Year stability

|

0.3%/year

|

|

Insulation

|

≥200MΩ(100VDC)

|

|

Ambient temperature

|

-20~60℃

|

|

Relative humidity

|

0~90%RH

|

|

Overload capacity

|

120%

|

|

Frequency response

|

100μs

|

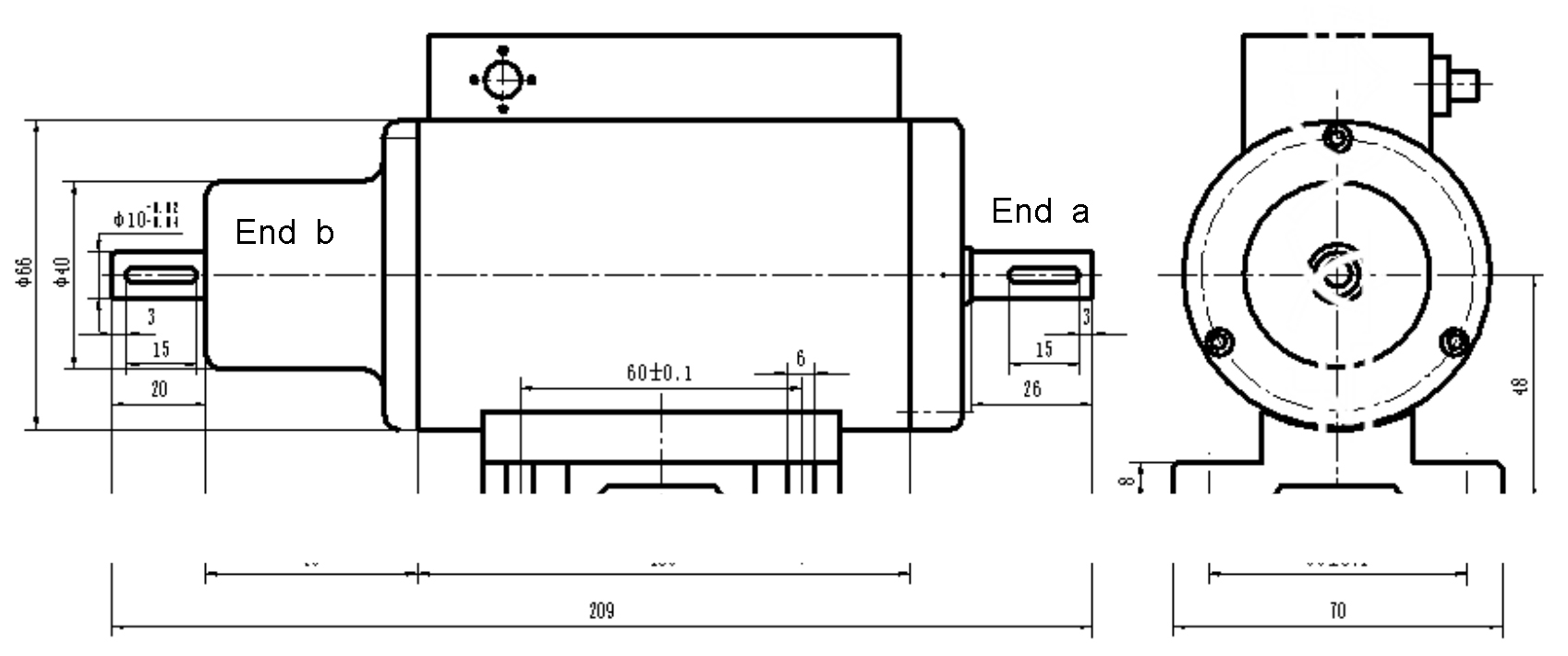

Installation

YGX-TQ1101 torque sensor has ends a and b, end b is for the measurement side, end a is for the auxiliary.

End b connect with the device to be tested through the coupling, the installation must be to avoid additional bending.

Horizontal installation

Axial installation

Note: Drawings can be seen by enlarging the scale

Use Note:

1. wiring must be correct;

2. ± 15V range: not less than ± 14.5V shall not be higher than ± 15.5V;

3. Signal wire output shall not be on the ground, the power short circuit, the output current is not greater than 10mA;

4. The shield layer of the shielded cable must be connected to the common end (power ground) of the ± 15V power supply.

5. The sensor elastomer is very fine and samll, strictly limit the overload, overload range ≤ 20%, or easily damaged.

6. If you have any questions, please contact us in time, the warranty period shall not be demolished.

Commonly used signal types and ancillary products

1. Directly send the torque frequency signal to the computer or PLD for processing;

2. Supporting XSM torque display, direct display torque value;

3. Match YGX-TQ1101 series torque speed power meter directly display torque, speed and power values;

4. Match F/I or F/V signal conversion module, the frequency signal is converted to 4-20m A or 1-5V and other commonly used analog signal to facilitate customer signal acquisition.

5. Selection of my company's professional data acquisition card and supporting software to achieve torque, speed and other signal acquisition, storage, printing, playback and other functions.