Model: YGX-TQ805 Thin disc type dynamic torque sensor

1. Applications

YGX-TQ805 dynamic disk torque sensor uses ultra-thin flange connection structure, ideally suited for test bench applications, such as engine, dynamometer and electric motor test stand, wheel load simulation test bench, gearbox and pumps test stand and other applications. Also mainly used for:

1. Motors, engines, internal combustion engine etc rotary power device output torque and power detection

2. Fans, pumps, gearbox torque and power of detection;

3. Railway locomotives, cars, tractors, aircraft, ships, mining machinery in the torque and power of detection;

4. Can be used in sewage treatment systems in the torque and power of detection;

5. Can be used in the process industry and process industry.

2. Features

The torque sensor is developed on the basis of standard torsion strain sensor, YGX-TQ805 dynamic disk torque sensor is the shortes structure of the axial length dynamic torque sensor.

1. No bearing structure, high-speed operation.

2. The signal output can be arbitrarily selected waveform ─ square wave or pulse wave.

3. Detection of high accuracy, good stability, strong anti-interference.

4. No need to repeatedly adjust to zero; continuous measurement of positive and negative torque.

5. Can measure static torque, but also can measure the dynamic torque.

6. Small size, heavy sensor can be used independently from the secondary instrument, just as the socket pin number provided + 15V, -15V (200mA) of power, you can output, square wave or pulse wave impedance and frequency signal proportional to the torque. Light weight, easy to install.

3. Range: 0~5000Nm

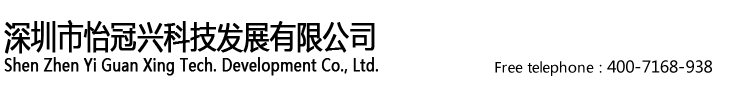

4. Dimensions(mm):

| Range(N.m) |

A |

L |

L1 |

D0 |

D1 |

D2 |

D3 |

D4 |

D5 |

D6 |

b |

a |

c |

d |

H |

h |

M |

| 5,10,20,50,100 |

65 |

120 |

95 |

114 |

50 |

50 |

86 |

78 |

40 |

40 |

7.5 |

44 |

7 |

12 |

143 |

86 |

8 |

| 200,500 |

65 |

150 |

120 |

144 |

70 |

70 |

116 |

108 |

56 |

50 |

10.5 |

38 |

9 |

12 |

179 |

107 |

12 |

| 1000,2000 |

65 |

180 |

150 |

170 |

95 |

95 |

140 |

136 |

60 |

60 |

11.5 |

38 |

11 |

15 |

202 |

117 |

14 |

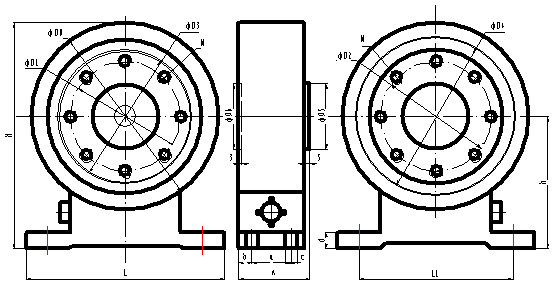

Dimensions : 5000~13000Nm

5.Specifications

|

Rated output

|

1±0.2 mv / V

|

|

Torque indication error

|

<± 0.5 % F.

|

|

Non-linearity

|

<±0.25 % F· S

|

|

Repeatability

|

<±0.2% F·

|

|

Return difference

|

<0.2 % F· S

|

|

Zero balance

|

<0.5 % F· S (24hours)

|

|

Temp. effect on zero

|

<0.5 % F· S /10℃

|

|

Output impedance

|

1KΩ ±3Ω

|

|

Insulation resistance

|

>500MΩ

|

|

Static Overload

|

120 %

|

|

Breaking load

|

200 %

|

|

Operation temp range

|

0 ~ 60℃

|

|

Storage temperature

|

-20 ~ 70℃

|

|

Voltage

|

+15V±5%, -15V±5%

|

|

Total current consumption

|

<130mA

|

|

Frequency signal output

|

5KHz—15KHz

|

|

Negative rated torque

|

5KHz±10Hz

|

|

Zero torque

|

10KHz±10Hz

|

|

Positive rated torque

|

15KHz±10Hz

|

|

Signal duty

|

(50±10)%

|

6.Installation

1. YGX-TQ805 dynamic disk torque sensor is composed by a stationary housing and the rotating disk two parts.

2. The two ends of the rotating disk are connected with the power and the load through the flange coupling..

3. Stationary housing fixed to the base, adjust the gap to ensure non-contact between the stationary housing and the rotating disk!

7.Signal acquisition and signal output

1. The basic form of torque signal output:

• Square wave signal, pulse signal, 4-20mA, 1-5V, 0-5V, 0-10V.

• According to the user needs, can be made into a voltage analog signal output or current analog signal output (one-way, static torque measurement).

2. The form of the torque signal processing:

• Torque sensor output frequency signal to a digital frequency meter or meter directly to reads the frequency or voltage signal proportional to the torque current signals.

• Torque sensor torque frequency signal to the microcontroller secondary instrument directly displays real-time torque value, speed and output power and RS232 communication signals.

• Torque and speed frequency signal directly to the computer or PLD for processing.

8.Maintenance:

1. No bearing structure, maintenance-free refueling.

2. It should be stored in a dry, non-corrosive, room temperature -20 ℃ --70 ℃ environment.

9. Precautions:

1. Installation, operation can not be charged and must not directly beat, the collision torque sensor.

2. The coupling of fastening bolts should be tightened, the protective cover should be added to the outside of the coupling, to avoid personal injury.

3. The output signal line can not be on the ground and power supply short circuit, the output current is less than 10mA , shielded cable shield layer must be connected to + 15V power supply common (power ground).

4. Radial runout shall not be greater than 0.5mm!

5. If in doubt in using, please contact our company,it can not be disassembled during the warranty period.